About Our Business

We bring customers solutions that integrate our capability to develop and design automatic machines with our contract manufacturing services

Matsuya R&D leverages over 40 years of experience in the sewing machine industry as well as a wealth of patents and advanced automatic and labor-saving sewing machine technology to help customers improve productivity.Our current operations, focused on the medical healthcare and safety system businesses, employ our own unique business model combining the design and development of original automatic machines with contract manufacturing using these machines.Working at the crossroads of automatic machine sales and contract manufacturing, we are uniquely positioned to meet customers’ exact needs.

[Building a business model like no other in the world]

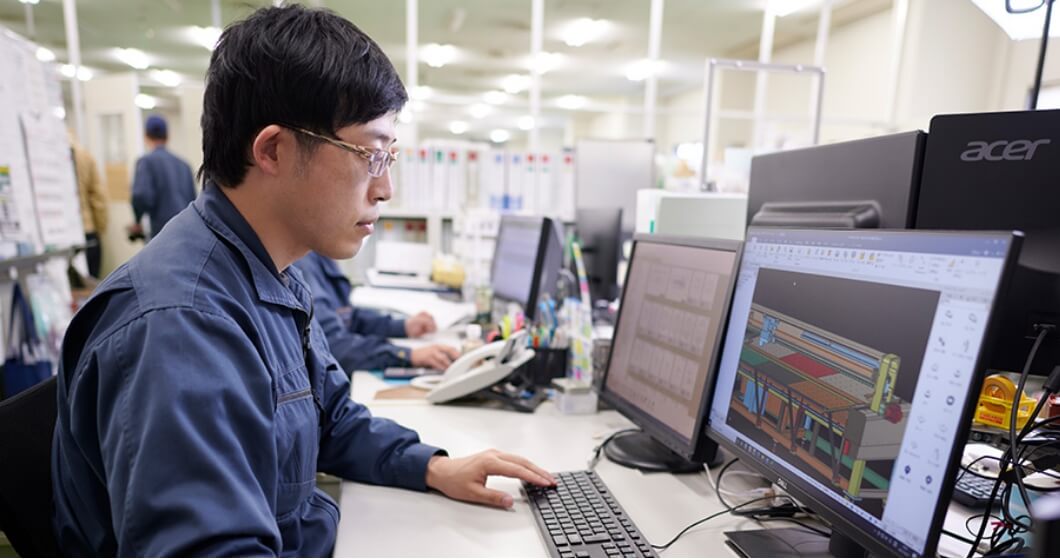

Equipped with unparalleled experience and knowledge of sewing automation, Matsuya R&D has an advantage in achieving significant cost reductions by designing production lines that employ its own equipment.

We have used our own technologies to implement digital transformation, realize traceability, and develop error-proofing solutions that improve production efficiency for further cost reductions.

At our 40,000-square-meter factory in Vietnam, we are engaged in contract manufacturing using our unique technology and know-how.

The Matsuya Innovation Center (MIC) located on the premises of the factory provides state-of-the-art manufacturing facilities and systems at low cost.

Delivering solutions to customers in the sewing market

Features of automatic machine design and development

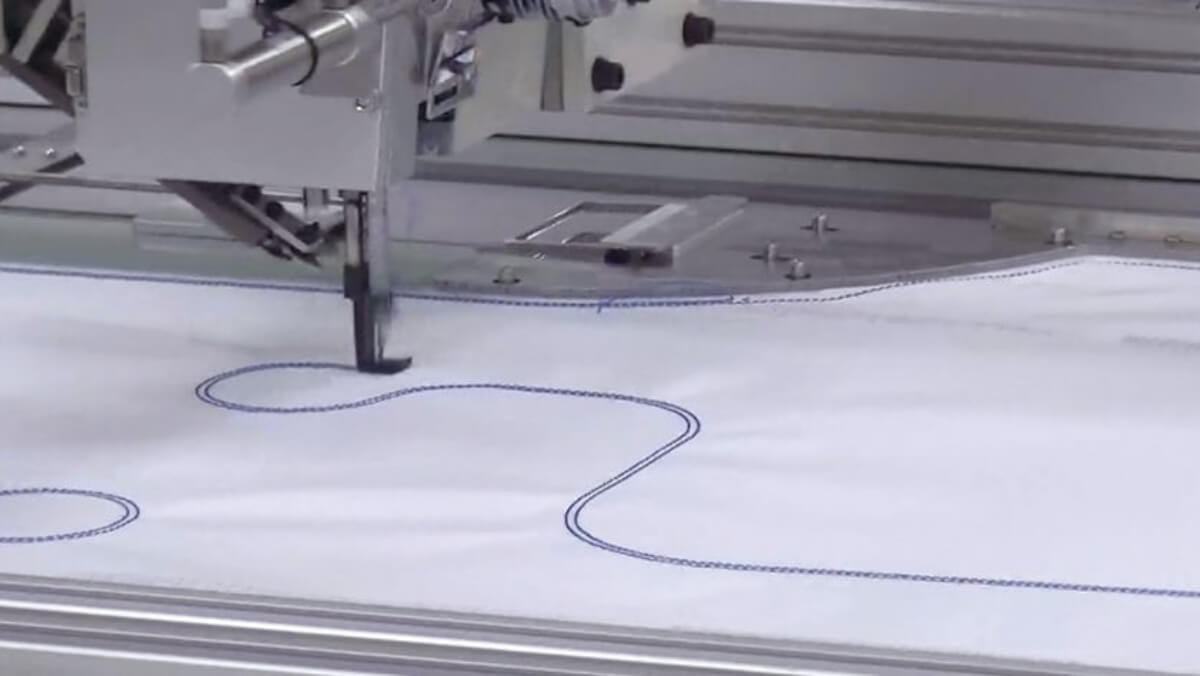

We develop systems that can fully automate any sewing process, even complex or 3D sewing

With over 40 years of experience in the sewing industry, Matsuya R&D has the ability to design and develop software for all kinds of sewing-manufacturing lines.We provide consulting tailored to your exact needs, whether it be the type of process and sewing required for your operations, or your desired lead time.We provide total support right from the planning and development stage to offer an automatic sewing robot that best meets your needs.

The only company that handles all production processes, from cutting to sewing

- Cutting

- Laser cutting machine

- Welding

- Silicon pasting machine

- Sewing

- Various high-end automated sewing machines

- Inspection

- Folding machine, air leak detection device, etc.

We also provide a wide range of other original, specially designed automatic machines.

View all our automatic machinesWe are expanding into the realm of IT to offer 3D sewing systems using AI robots and more

We have made inroads into the IT industry with the development of general-purpose programming software for 3D sewing robots equipped with a vision system.

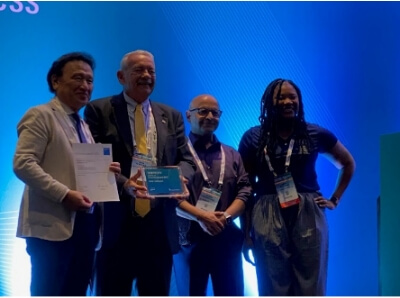

An intelligent robotic sewing machine equipped with a digital image processing system developed by the Matsuya Innovation Center (MIC) in Vietnam won the Innovation Award in the New Concept category at Texprocess Americas 2023 held in Atlanta, USA in May.We will continue to develop, mainly at MIC, a variety of automatic machines that provide solutions to the global labor shortage.

Watch videos of some of the systems we have designed and developed

Dual-Arm 3D Sewing Robot System featuring a 2-Needle Overlock Sewing Machine

6-Axis Robotic 2-Needle Overlock 3D Sewing System

Features of contract manufacturing

Our contract manufacturing for sewn products cuts your production costs and ensures stable quality

Unlike conventional sewing factories, we work with customers to develop and produce automatic sewing systems incorporating all our expertise before starting contract manufacturing.

Our contract manufacturing takes place at our factories using our own automatic machines.

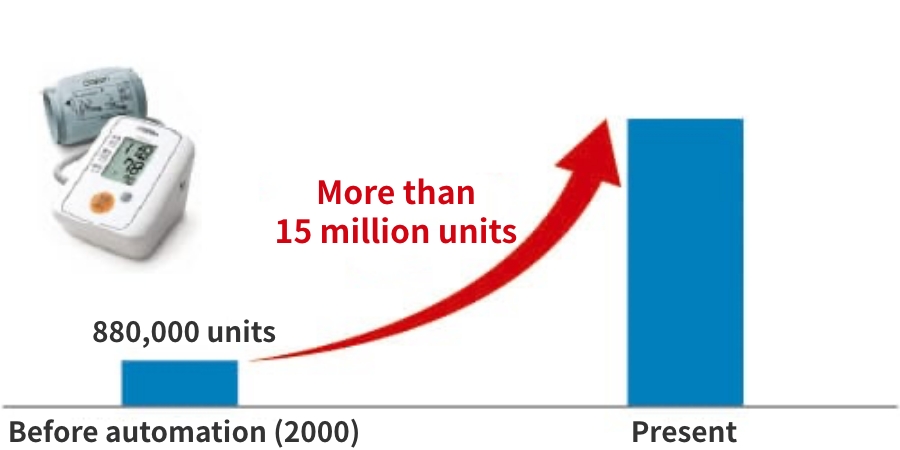

Our OEM production handles over 50% of the world’s total market share of blood pressure cuffs

We used our sewing know-how and special technology to automate the sewing line for blood pressure cuffs.

We opened a new OEM factory in Vietnam in 2023 to further strengthen and expand our contract manufacturing services

The Vietnam factory engages in contract manufacturing using cutting-edge production equipment and systems provided at a low cost by the Matsuya Innovation Center, which is located right on its premises.Going forward, we will operate our factories across the globe using the same model to expand our contract manufacturing services.

We will also open a showroom at the Vietnam factory, which is equipped with cutting-edge equipment, to promote our technology and expertise to more widely expand the customer base for our automatic machines.

Other OEM factories in Japan and overseas

Products manufactured on our OEM lines

- Growth Strategy

- Our growth strategy focuses on expanding our unique business model that combines design and development of automatic machines with contract manufacturing to deliver solutions to customers; launching new businesses in the medical, mobility, environment and energy sectors; as well as contributing to digital transformation in manufacturing by expanding sales of systems developed in-house.

- Focus AreasMedical

- We are streamlining the manufacturing of medical protective clothing and hygiene products to facilitate a shift to domestic production.

- Focus AreasMobility

- With over 30 years of experience in automobile interior components,we are committed to creating a safer and more comfortable automotive society.